Band Saw

Cutting Speed 22-65 rpm

Main Motor 1.1-380 kW/V

SIK SORULAN SORULAR

A band saw machine is a machining machine where a band saw is mounted on a fixed platform and designed to make various cuts. It usually includes a large cutting surface, material guides and various adjustment mechanisms. This machine enables precise and smooth cuts and is used in various industries such as metalworking.

A band saw is a machine with a long, thin and continuous blade consisting of a series of toothed blades. The principle of operation is as follows:

Blade Movement: The blade of the band saw is tensioned between two wheels (usually top and bottom). The wheels move the blade by continuous rotation.

Material Placement: The material to be cut is placed on the workbench and brought to the appropriate position.

Cutting Process: The rotating blade moves back and forth to cut the material. The blade teeth work efficiently when cutting the material.

Adjustments and Guides: Guides and adjustment mechanisms on the workbench allow adjusting the angle and depth of cut, so that the desired type and precision of cut can be made.

The band saw provides smooth and precise cuts thanks to the continuous rotation of the blade as it cuts the material.

The points to be considered when using a band saw machine are as follows:

Safety Equipment: Always wear personal protective equipment such as goggles, ear protection and gloves.

Blade Tension: Check the blade for proper tension. An excessively loose or tight blade can affect the quality of the cut and reduce the performance of the machine.

Blade Condition: Make sure the blade is sharp and in good condition. Worn or damaged blades can cause problems during cutting.

Material Placement: Place the material neatly on the workbench and prevent the material from slipping by using the appropriate guides.

Cutting Speed and Pressure: Avoid applying excessive speed and pressure during the cutting process. Set the appropriate speed and pressure to allow the blade to cut the material smoothly.

Safety Guards: Use the safety guards on the machine and make sure they are always in place.

Emergency Stop: Know and be prepared to use the machine's emergency stop button and other safety mechanisms.

The metal types that can be processed with a band saw are as follows.

Steel: Band saws can cut different types of steel, but it is important to use the correct blade and settings. Steel is generally harder and more durable, so choosing the appropriate blade tooth is essential.

Aluminium: Aluminium must be cut with special blade teeth as it is a softer metal. A band saw can cut aluminium cleanly and smoothly.

Stainless Steel: Stainless steel has high wear resistance, which can have an impact on the life of the blade when cutting. Special blades and low speed cutting are preferred.

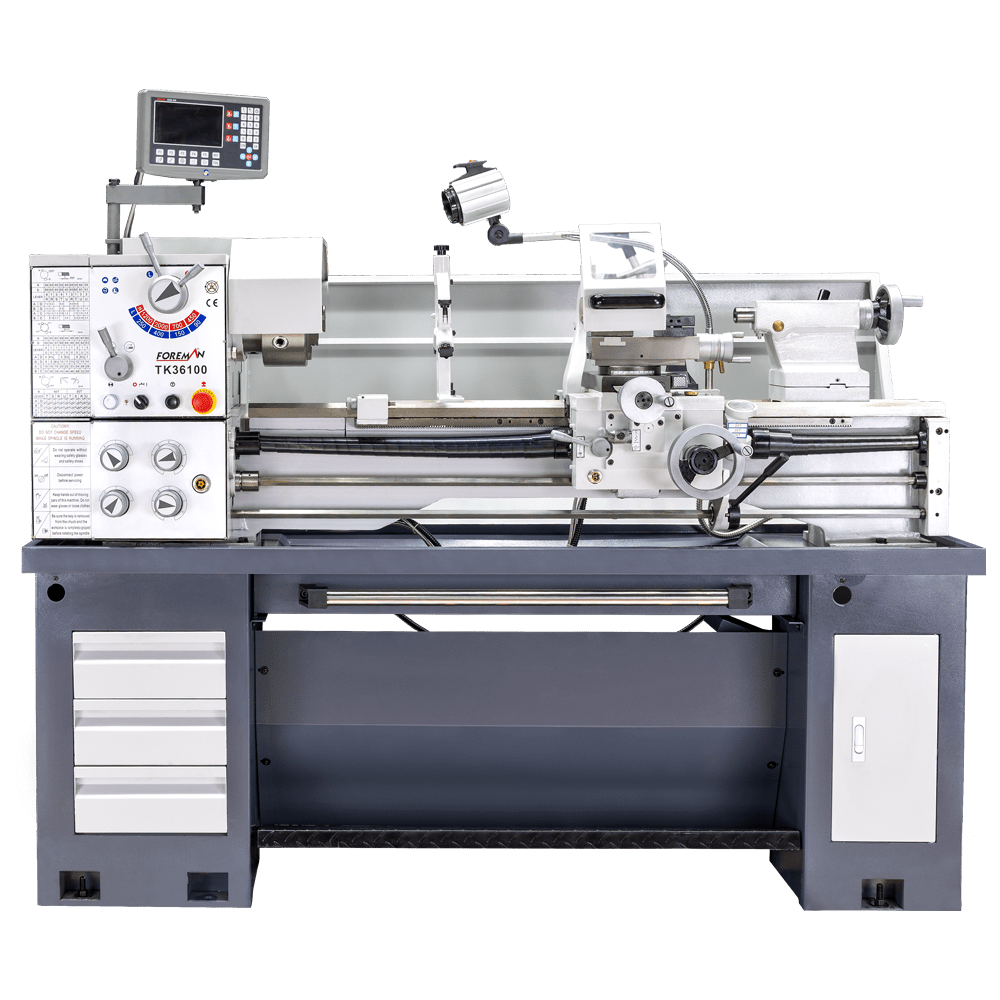

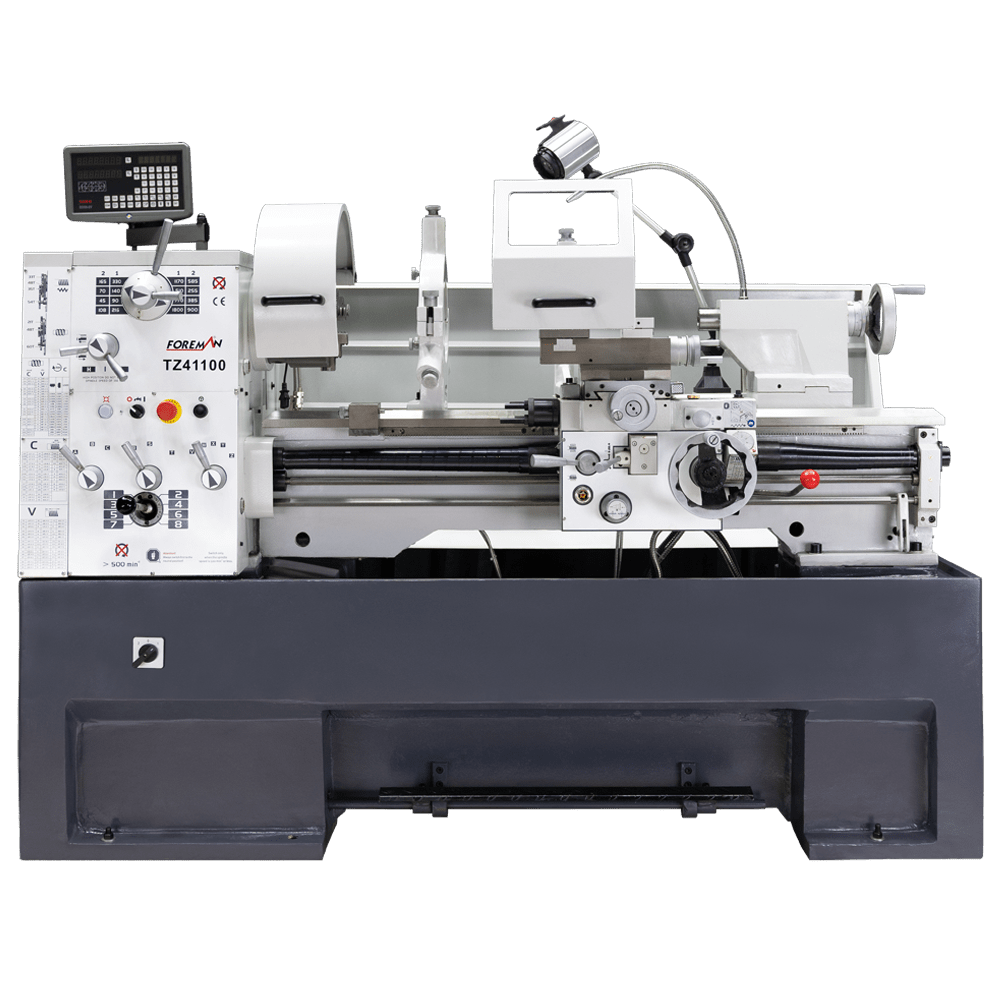

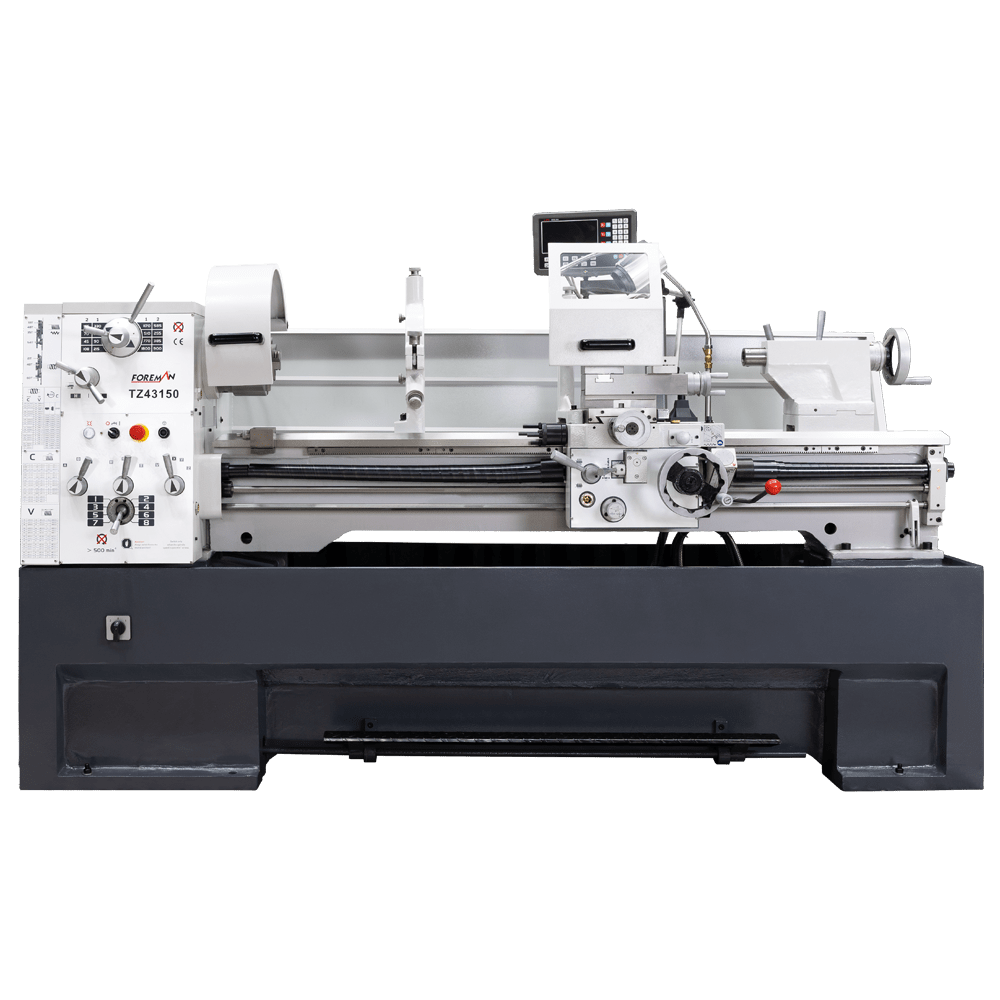

We provide the fastest service to our customers with our rich spare parts stock and professional service network. Original spare parts are supplied by Foreman instead of third party sellers. You can contact us when you encounter any problems with Foreman band saw bench models.

_zkmmzopp1k.jpg)